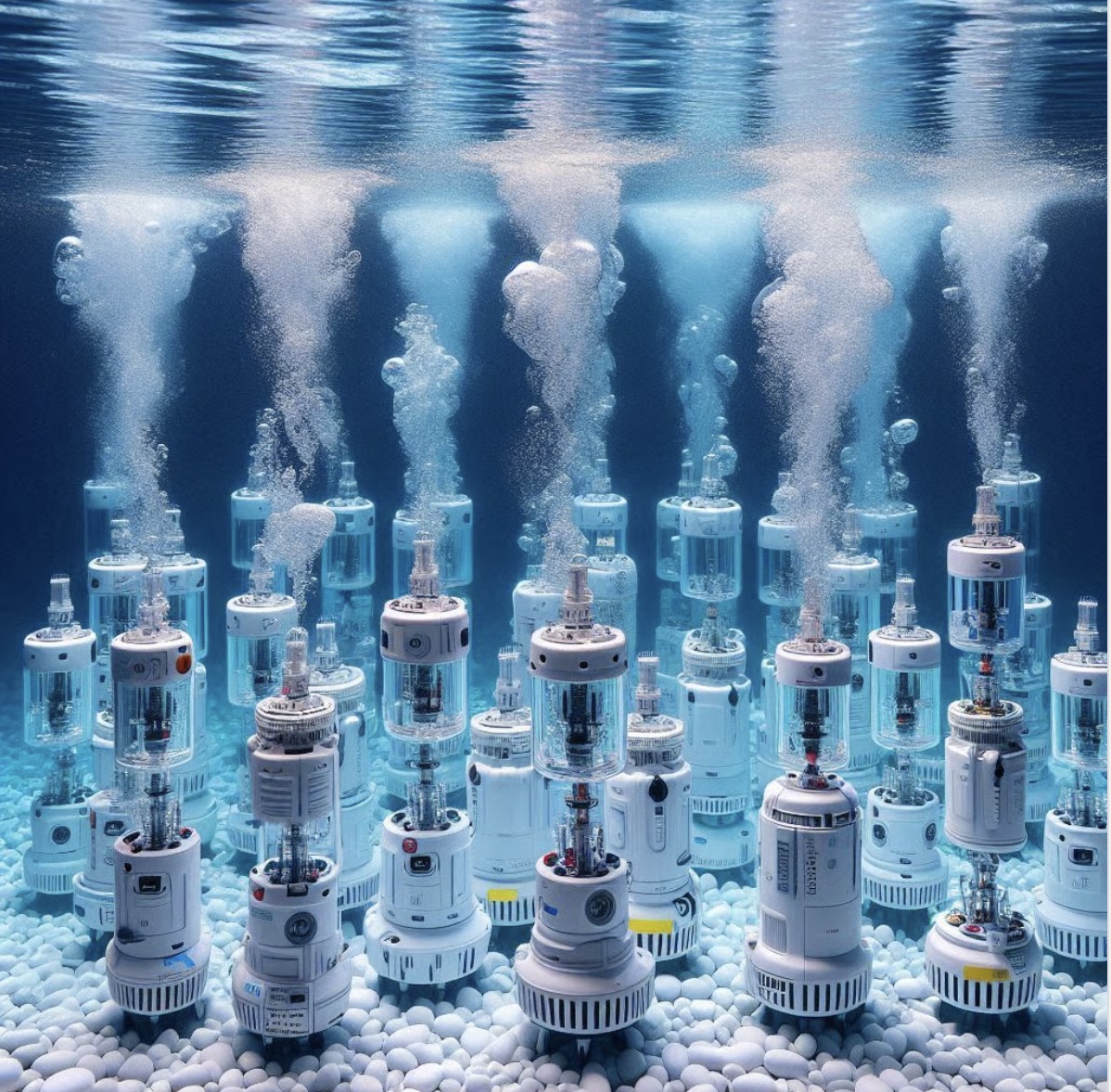

Electric Submersible Pumps (ESP)

£11500.00£10800.00

INTRODUCTION

This highly interactive training course is meticulously crafted to equip participants with a profound understanding of Electric Submersible Pumps (ESPs), encompassing their selection, installation, operation, and maintenance in both onshore and offshore oil production installations.

The Electric Submersible Pumps (ESPs) training course encourages active engagement through insightful discussions and Q&A sessions. It offers a platform to address specific challenges, fostering the discovery of optimal solutions. Participants will gain comprehensive insights into:

Mainstream ESP System Configurations

Alternative ESP System Configurations

Installation of ESPs in Challenging Environments

Selection and Operation of ESPs and Associated Drives

Installation, Monitoring, and Troubleshooting of ESP Systems

TRAINING OBJECTIVES

The Electric Submersible Pumps (ESPs) training course aims to empower participants to achieve the following objectives:

Acquire knowledge about various ESP Systems and their applications

Comprehend the components and equipment employed in ESP Systems

Explore ESP Pump Technology

Gain proficiency in ESP Selection and Performance Calculations

Understand the Advantages and Limitations of diverse ESP Drive Systems

Grasp the Power Supply Requirements of ESP Installations

Learn the essentials of installing, maintaining, and troubleshooting ESP systems

WHO SHOULD ATTEND?

This comprehensive training course is tailored for professionals directly involved in the design, selection, installation, operation, and maintenance of Electric Submersible Pumps. It will be highly beneficial for:

Project, Design, and Maintenance Professionals

Petroleum, Chemical, and Mechanical Engineers

Electrical Engineers

Field Operators and Technicians

Maintenance Engineers and Personnel

TRAINING METHODOLOGY

It adopts a holistic approach, blending presentations with interactive practical exercises, complemented by video materials, activities, and case studies. Participants are actively encouraged to share their specific requirements and challenges, facilitating dynamic group discussions. The course integrates detailed case studies and anecdotes, drawing from the facilitator's extensive field experience.

TRAINING OUTLINE

Day 1: Fundamentals of Electric Submersible Pumps

Introduction to ESPs and ESP Systems

A Historical Overview of ESPs

Design Considerations for Mainstream ESPs

Insights into ESP Pump Designs

Exploring ESP Motor Designs

Understanding Cabling Requirements

Motor Control Mechanisms

Miscellaneous Accessories

Alternative ESP Configurations

Inverted/Bottom Intake Configurations

Employing Dual and Triple ESPs in the Same Well

Boosters for ESPs

Day 2: Application of ESPs in Challenging or Harsh Environments

Onshore and Offshore Applications

Handling Multiphase Fluids

Managing Abrasive Contaminants

Dealing with High Temperatures and Corrosive Substances

Navigating Viscous Fluids, Emulsions, Scaling, and Asphaltenes

Offshore Challenges

Modular Requirements

Platform Cable Connections

FPSO Disconnectable Turret Swivel and Mooring System

Subsea Cabling and Electrical Connections

Subsea Equipment Deployment

Day 3: ESP System Selection, Performance Calculations, and Equipment Sizing

Establishing Fundamental Requirements

Assessing Well Production Capacity

Analysing Fluid Composition and Volume, Including Free Gas Volume

Calculating Total Dynamic Head

Selecting the Optimal Pump and Motor Type and Size

Configuring Downhole Cables

Identifying Suitable Drive Systems, Power Supplies, and Accessories

Variable Speed Drive Considerations

Design Examples

Day 4: ESP Monitoring, Control, Protection, and Installation

Downhole Monitoring and Sensor Utilisation

Leveraging Embedded Fiber Optic Cables for Monitoring and Sensing

Earthed (Grounded) and Unearthed (Ungrounded) ESP Motors

Addressing Earthing and Lightning Propagation in ESP Circuits

Electrical Protection Equipment for ESPs

Introduction to SCADA/EMS (ESP Management System) for Local and Remote Installations

Safety Measures and Shut-Down Systems

Day 5: Commissioning, Operation, and Maintenance

Commissioning Requirements and Procedures

Optimising Pre-Production Phases

Regular Operation and Monitoring Practices

Management of Maintenance Activities

Detecting and Responding to Abnormal Conditions

Troubleshooting Guidelines

Real-World Case Studies and Examples of ESP Problems and Failures

Equipment Servicing

Utilising Well Workover Rigs

Handling Cable Reels, Reel Supports, and Cable Guides

Shipping Cases and Transport for Long Shipping Cases

Factory Repair and Reconditioning

Summary and Open Discussion

Certificate of Completion: Upon successful completion of the course, participants will receive a Certificate of Completion from Al-Majd Pathways Centre (APC).

Get in touch with us today.

Follow

Sign-up for our newsletter

0044 7466410010

©2025 All rights reserved.